Our Services

Central Plastic & Rubber is dedicated to providing a comprehensive range of manufacturing solutions tailored to meet the diverse needs of our clients. With a keen understanding that every project demands unique expertise, we offer a suite of specialized services designed to address a wide array of applications.

Our commitment to excellence is evident in our careful selection of the most suitable techniques for each endeavor. Whether precision-cutting, shaping, or fabricating, we ensure that our clients receive the highest quality results. Explore our services below to discover how Central Plastic & Rubber can turn your concepts into tangible, custom-crafted solutions.

Die Cutting

Die cutting is a manufacturing process that uses specialized machines and sharp tools (called dies) to cut, shape, and form materials such as paper, fabric, rubber, and various composites.

Why Die Cutting?

- Precision and Efficiency: Allows for high precision and rapid production of identical shapes or parts.

- Mass Production: Ideal for high-volume production runs where consistent shapes are needed.

Die-Less Knife Cutting

Unlike die cutting, die-less knife cutting doesn’t use a physical die. Instead, it employs computer-controlled knives to cut through various materials.

Why Die-Less Knife Cutting?

- Complex Shapes: Suitable for intricate designs or irregularly shaped pieces where a physical die would be impractical.

- Prototyping and Short Runs: Effective for small-scale production or rapid prototyping.

Thermoforming

Thermoforming is a process where a plastic sheet is heated to a pliable forming temperature, shaped, and trimmed to create a final product.

Why Thermoforming?

- Cost-Effectiveness: Offers a cost-effective method for producing large, hollow products compared to injection molding.

- Custom Shapes: Allows for the creation of custom-shaped plastic components.

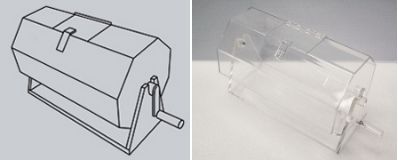

Custom Fabrication

Custom fabrication involves the creation of unique products or parts through various methods like cutting, bending, welding, and assembling raw materials.

Why Custom Fabrication?

- Bespoke Solutions: Tailored to specific customer requirements or projects.

- Prototyping and One-Offs: Ideal for creating custom or one-time pieces.

Skiving

Skiving is a process of thinning materials, often involving the removal of layers from a surface.

Why Skiving?

- Precision Thickness: Achieves precise thickness for materials like leather, foam, or rubber.

- Consistency: All layers have the same required thickness.

CNC Machining

CNC (Computer Numerical Control) machining involves using computer-controlled tools to remove material from a workpiece to achieve a desired shape or structure.

Why CNC Machining?

- High Precision: Offers exceptional accuracy and repeatability.

- Versatility: Can be used on a wide range of materials, including metals, plastics, and composites.

Water Jet Machining

Water jet machining uses a high-pressure stream of water (sometimes mixed with abrasive materials) to cut through various materials.

Why Water Jet Machining?

- No Heat-Affected Zone: Suitable for materials sensitive to high temperatures.

- Versatility: Works on a wide range of materials, including metals, glass, stone, and composites.

Plastic Welding

Plastic welding is a process that joins thermoplastic materials together using heat, pressure, or both.

Why Plastic Welding?

- Seamless Joints: Creates strong and durable connections between plastic parts.

- Repair and Fabrication: Used for both repairing existing plastic components and creating new ones.

Contact Us

Let’s bring your product to life

Whether you want to learn more about our services or receive a quote, our experts are here to help. Call the number below or fill out our contact form, and we’ll be in touch soon.